Table of Contents

The Foundation: Why Substrate Matters

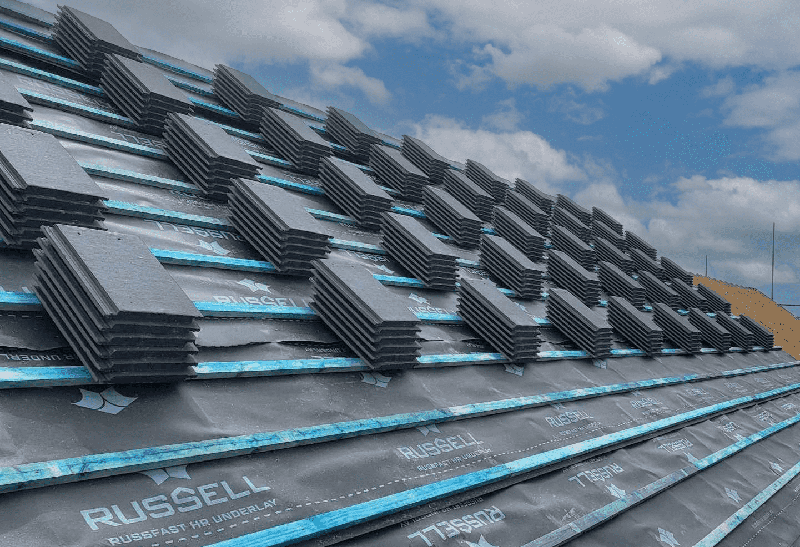

Expertise starts before the top layer ever goes down. In our process, we don’t just cover up old problems. We ensure the decking is pristine and reinforced, followed by a premium SBS ice and moisture block. This acts as a secondary “fail-safe” for your home.

The Torch-Down Technique: Thermal Fusion Explained

The rolls you see our team handling are Modified Bitumen. While some contractors use simpler methods, we utilize the torch-down technique for maximum durability.

By using professional-grade torches to heat the membrane, we create a permanent, fused bond. Look for the uniform “bleed-out” at the seams in our photos—that’s the mark of a perfect melt that water cannot penetrate.

Detailing the Danger Zones: Vents & Edges

The most common failure point on any roof is a penetration (vents, pipes, or skylights). We hand-weld the membrane to the flashing to create a monolithic seal, ensuring that these high-risk areas are the strongest parts of your roof.

The Expert Advantage: SBS vs. Standard Asphalt

We use SBS (Styrene-Butadiene-Styrene), a high-grade polymer that makes asphalt more flexible. Unlike standard roofing that can become brittle and crack in the cold or “flow” in the heat, SBS expands and contracts with your building, significantly extending the life of the roof.